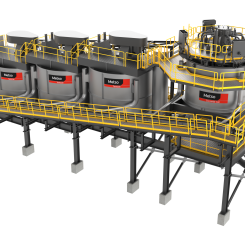

Metso is launching a redefined OKTOP® Conditioner product series, designed to enhance flotation performance in minerals processing. The Conditioners are located before the flotation circuit, and their primary function is to prepare a homogenous slurry by mixing it with flotation reagents. This ensures optimal chemical contact and residence time, which are critical factors for maximizing flotation cell circuit performance.

“Metso’s streamlined OKTOP Conditioner series is designed to unlock the full potential of flotation cells and circuit efficiency. The series includes improved features, such as Metso’s latest agitator design to give the best durability and minimize chemical consumption. The solutions integrate effortlessly with any flotation unit, such as Metso TankCell® and Concorde CellTM, and enable fast design, installation and commissioning,” said Ville Strömmer, OKTOP Reactors Product Manager from Metso.

The OKTOP Conditioners can be used for various applications, such as oxidized sulfide ores, silicates, phosphates, copper-molybdenite separation, complex sulfides like nickel and copper, PGM metals, and more. Optional features can be added to add even more flexibility and control to the operation.

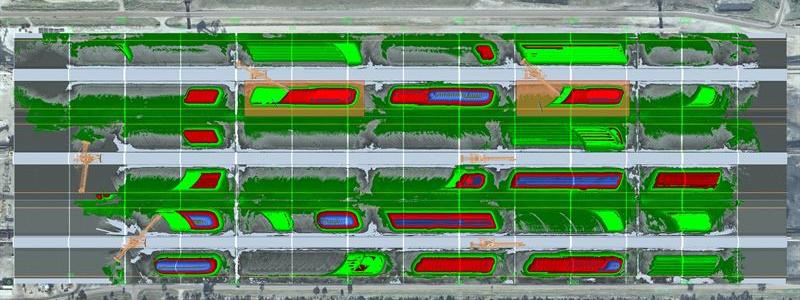

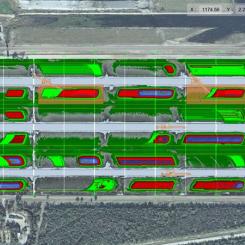

In parallel, Metso is introducing a new Resource Center, which offers customers and Metso experts instant access to 3D models, GA drawings and foundation layouts for OKTOP equipment. With pre-engineered, proven designs for OKTOP Conditioners, the Resource Center simplifies equipment selection and reduces engineering time and costs, thus accelerating early project phases. Designs for other agitated reactor products will be added soon.

Metso is recognized as a leader in flotation technology, combining decades of expertise with continuous innovation. Its offering spans testing, equipment, automation, and services, enabling customers to achieve maximum metallurgical performance and sustainability goals.