The Finnish industrial water treatment company Epse Oy, based in Ylöjärvi near Tampere, has signed two major international agreements to export its mine water purification technology to Uzbekistan and Kazakhstan. Each project is valued at around €200 million and is expected to generate recurring annual revenues for the company over the coming years.

The agreements were concluded during President Alexander Stubb’s official visit to Central Asia, where Epse took part in the Finnish business delegation alongside some 20 other companies.

– President Stubb’s help was crucial for making this deal happen, said Epse CEO Jouni Jääskeläinen in an interview with Yle.

Joint venture with Uzbekistan

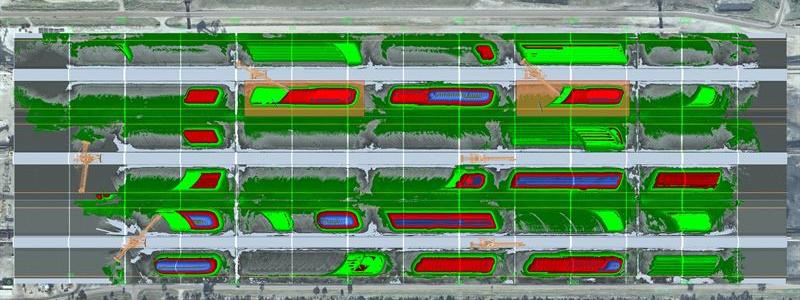

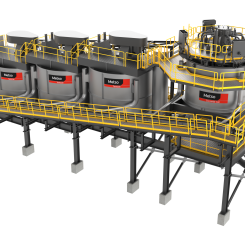

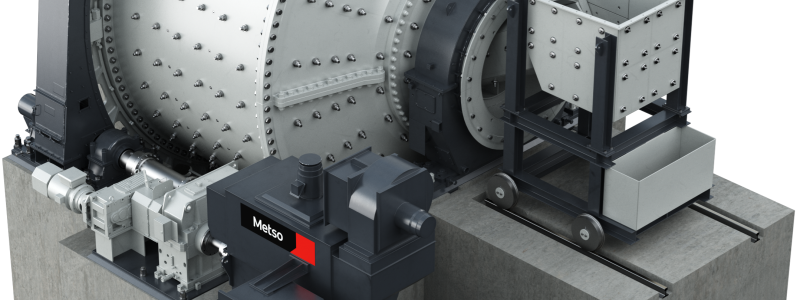

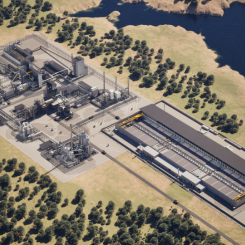

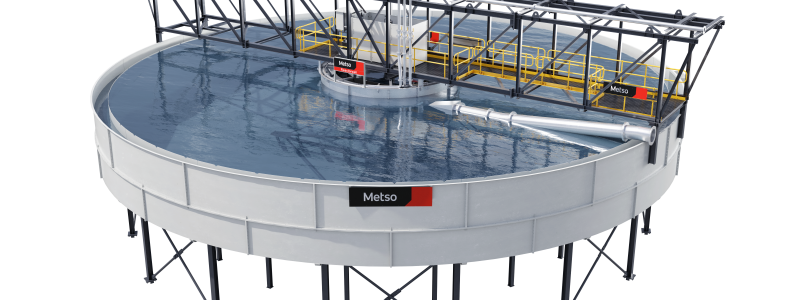

In Uzbekistan, Epse and its US-affiliated subsidiary Epse Technology signed an agreement with the country’s Ministry of Mining and Geology to establish a joint venture. The first project involves constructing a Green Zone unit – a treatment plant designed to clean contaminated water from mining operations and reduce heavy metal pollution in soil and groundwater.

The facility is scheduled for completion within two years and is expected to begin operation in 2027. The deal also includes an option to build five additional units in the country.

Epse also signed a memorandum of understanding earlier in the week with a state-owned company in Kazakhstan for a similar initiative.

– This is a major opportunity for us. It’s not just a single project but a long-term cooperation, said Jääskeläinen.

– The Green Zone units will require our proprietary chemicals worth around €2 million annually.

Technology that recovers metals and reuses water

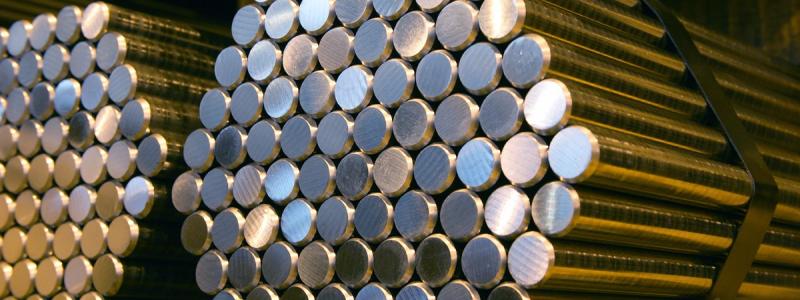

Founded in 2012, Epse specialises in the treatment of industrial processes and wastewater containing heavy metals. Its patented process uses chemical separation to bind metal ions to a special reagent that precipitates as a solid. The clean water can then be reused, while critical raw materials and rare earth elements are recovered from the residue.

– With the Green Zone concept, everything that enters the process is reused. Nothing is wasted, Jääskeläinen explained.

The method, developed and tested in Finland, reduces the need for tailings storage and minimises the risk of environmental contamination – an issue of growing concern for the mining industries in Central Asia.

Supported by the EU and Finland

The Uzbek project forms part of the broader Green Zone program, designed to support the country’s goals for sustainable industrial development and efficient resource management. The initiative is backed by the European Union’s Critical Raw Materials (EU CRM) program and the Finnish government.

The program also aims to foster local technological expertise and job creation. According to Epse, between 100 and 150 local workers will be employed for the construction and operation of the facilities, while Finnish specialists may take part as project managers and technical supervisors.

In Finland, the company plans to expand its current 15-person workforce as international operations grow.

Rapid growth for a small Finnish company

Epse’s financial growth has been significant. The company’s turnover increased from €400,000 in 2022 to €6 million in 2023, and the new Central Asian ventures are expected to accelerate this expansion. Epse’s business model combines the sale of purification technology with recurring revenue from the chemical reagents used in the process – providing a stable income stream over time.

Epse’s approach aligns with a global trend linking environmental technologies to the recovery of valuable raw materials, an area gaining strategic importance for both the EU and Finland. Europe seeks to reduce dependence on imported materials, especially from China, and is supporting technologies that enable metal recovery from industrial waste.

Uzbekistan and Kazakhstan are among the world’s largest producers of minerals such as uranium, copper, and rare earth metals, but both countries face serious environmental challenges and lack robust regulatory frameworks. If successfully implemented, Epse’s technology could help reduce the environmental impact of mining in the region – though long-term success will depend on local governance and maintenance capacity.

Jouni Jääskeläinen emphasised that cooperation with the Uzbek government represents a strategic milestone.

– This gives us a chance to demonstrate what our technology can achieve on a full industrial scale, he said.

Epse hopes that the Central Asian projects will become reference sites for future exports to other mining regions, including Africa and Latin America, where similar pollution issues persist.

Source: Yle / Epse Oy

Fact check:

Epse Oy’s process is based on chemical precipitation that separates heavy metals from industrial wastewater. The method has been tested in Finland and reportedly meets international environmental standards. Uzbekistan faces major challenges from contaminated mine water, especially in uranium and copper mining regions. The Green Zone program aims to reduce such pollution while recovering critical materials.