Metso has signed a three-year agreement for the supply of metallic liners for chute solutions to BHP. The value of the agreement is not disclosed.

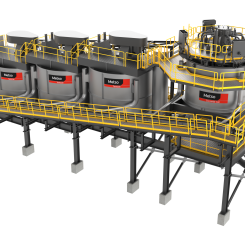

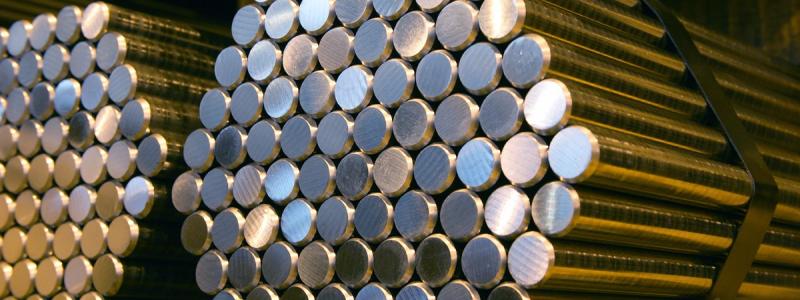

Under the terms of the contract, Metso will support BHP’s Western Australia Iron Ore (WAIO) operations with a suite of liner solutions, including its industry-leading XAlloy™ metallic as well as cast wear liners, amongst others. Metso offers a wide range of protective chute lining solutions in multiple materials to suit challenging customer duties. Metso’s lining solutions are renowned for their ability to minimize downtime and thereby maximize throughput and productivity.

“We are strongly focused on delivering better overall efficiency and productivity for our customer operations. With our extensive offering in chute liner designs, backed by decades of experience and innovation, we can deliver greater uptime, and safer, quicker maintenance for our customers,” says Tobias Krull, Director, Chute and Conveyor Solutions. “This contract further solidifies Metso’s position as a trusted solutions provider within the mining industry,” he adds.

Metso has a proven track record of delivering customized chute wear lining solutions for various mining applications, with a strong emphasis on safety, performance, and durability. Xalloy™ wear linings, for example, are manufactured using state-of-the-art welding technology to apply a highly alloyed chromium carbide-based material to a mild steel backing plate.

Adding to the capability of customized solutions, Metso has a solid manufacturing presence in Australia, featuring advanced foundry operations and specialized rubber and Poly-Met production. Additionally, the company has a significant service center footprint in Australia, including Karratha in Western Australia, which is Metso’s largest service center globally. This extensive manufacturing and services capability further enhances the company’s commitment to locally serve its customers close to their main mining areas.