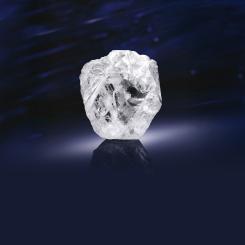

Now operating on two continents, Alcoa has successfully completed the installation of press filtration technology for bauxite residue at our Poços de Caldas refinery in Brazil, further leveraging technology that Alcoa first adapted in Australia.

“We’re so proud of our team and the work to achieve our corporate vision to reinvent the aluminum industry for a more sustainable future,” said Fabio Martins, Poços Plant manager. “As we bring this technology online, we’re marking a new era of innovation and sustainability for Alcoa in Brazil. In addition to the innovation in the process, the installation of the filtration plant will reduce carbon emissions, due to the lower use of disposal area, lower water accumulation and, consequently, lower energy consumption in the process.”

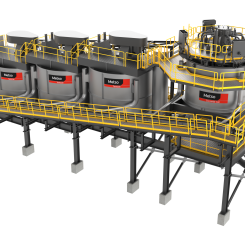

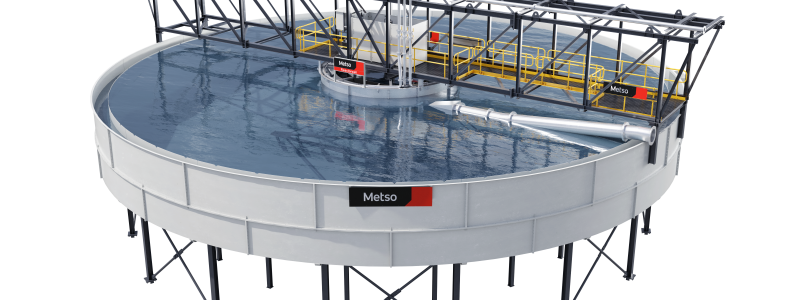

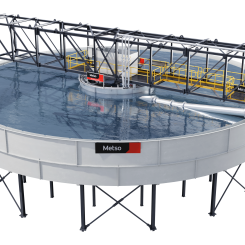

The press filtration plant is the first for Alcoa in Brazil, allowing our facility to use less water to process the residue and less land to store it. Alcoa first adapted the filtration technology to the treatment of bauxite residue at the Kwinana and Pinjarra refineries in Western Australia. Those two refineries have the annual capability to reduce their freshwater use by a collective 2.2 gigaliters (581 million gallons), the equivalent amount of water needed to fill 880 Olympic-sized swimming pools.

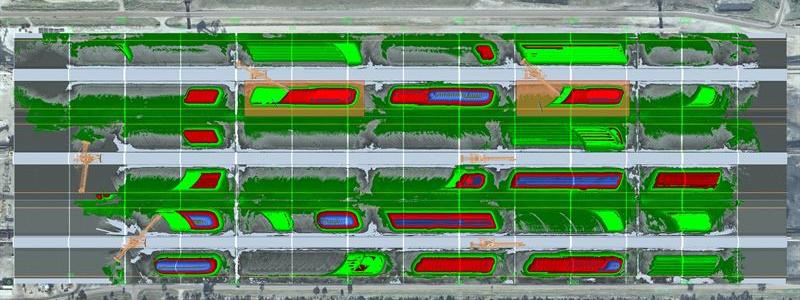

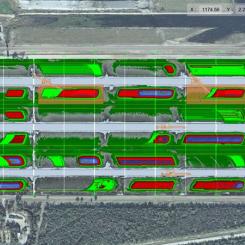

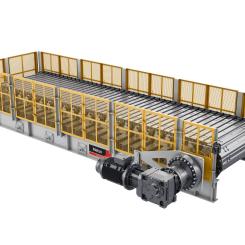

The filtration plant processes the residue, which is primarily composed of red mud and coarse sand. The residue is pumped into the filter, where plates compact it, removing approximately 70 percent of the moisture. The recovered water is then returned to the refinery’s production process through a closed circuit. The waste that remains is like the moisture content in soil, which is then transported by trucks to a new dry disposal area for further compacting.

Globally, deployment of these innovations connects to Alcoa’s strategic long-term goal to reduce bauxite residue land storage requirements by 15 percent by 2030 from a 2015 baseline. Further improvements are expected with enhanced solar drying and adaptation of residue filtration technologies.

Construction of the press filtration facility in Brazil began in late 2021. Today, all of the refinery’s bauxite residue is now being processed through the filter system to yield dry waste. The team worked more than 800,000 hours throughout the span of the project without a safety incident.

The reduction of bauxite residue is also one of several process improvements Alcoa is developing for its Refinery of the Future project, which intends to unlock decarbonization at scale and deliver a cost-competitive refinery that can eliminate fossil fuels from the refining process and bring other operational improvements.

Poços de Caldas, Alcoa's first operation in Brazil, was brought online in 1965. Operations include mining, refinery, chemicals, remelting and aluminum powder operations – the only one in the Alcoa system in the world.