Rare earth metals are not as scarce as their name suggests, but they are essential to the digital economy and the energy transition. These 17 metals are found in electric vehicles, batteries, displays and the generators inside wind turbines. Europe depends almost entirely on Chinese suppliers, making the supply chain highly exposed. At the same time, conventional separation techniques are extremely energy-intensive, chemical-heavy and environmentally damaging.

At ETH Zurich, a research group led by Victor Mougel has now developed a significantly simpler separation technique for europium. The findings were recently published in Nature Communications.

– Rare earth metals are hardly ever recycled in Europe, said Mougel in the original article. He emphasised that the need for sustainable and uncomplicated recovery methods is urgent.

The new process allows europium to be separated from complex mixtures of other rare earth elements far more efficiently than existing industrial methods.

Inspired by natural molecular structures

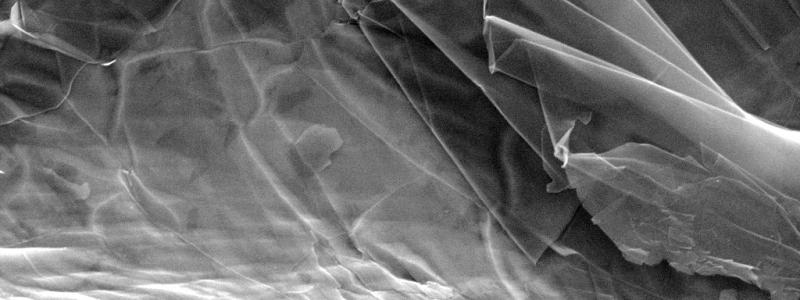

Traditional separation relies on hundreds of liquid–liquid extraction steps, making europium recycling economically unrealistic. In the new study, researcher Marie Perrin demonstrates that an inorganic reagent – a tetrathiometallate – can dramatically simplify the process.

– This allows us to obtain europium in a few simple steps and in quantities at least 50 times higher than previous methods, Perrin said.

Tetrathiometallates occur naturally in biological enzymes and are used in fields such as cancer research. The ETH team found that these molecules reduce europium to its uncommon divalent form, which in turn makes separation from the normally trivalent rare earth metals much easier. It is the first time these molecules have been used as ligands for rare earth separation.

The method opens the door to practical europium recovery, especially from electronic waste – a rich raw material source that remains largely unused today.

Electronic waste as a European resource

Electronic waste contains high concentrations of rare earth metals, yet the EU’s recycling rate remains below one per cent. The Zurich team notes that Switzerland could recover europium from lamp waste that is currently exported for landfill disposal.

Europium has historically been used as a phosphor in fluorescent lamps and screens. As these products are phased out, demand has fallen, making older recycling methods economically unviable. However, the europium concentration in lamp waste is around 17 times higher than in natural ores, making it a highly attractive source – provided separation can be done efficiently.

The researchers highlight that their approach is far more environmentally benign than extraction from mined ore. The team has filed a patent and is now developing a start-up, REEcover, to commercialise the method.

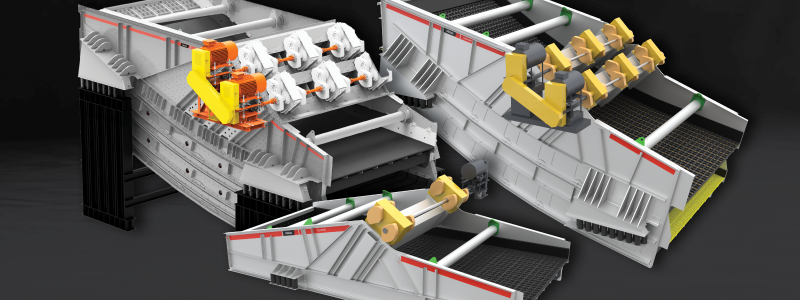

The next step is to adapt the separation strategy to other critical elements such as neodymium and dysprosium, both vital components in magnets for electric vehicles and wind turbines. Successful recycling of these metals would help Europe reduce its dependence on imported raw materials in a market already strained by rising demand and supply-chain uncertainty.

Fact:

The study, published in Nature Communications, presents a new europium separation and recovery method based on tetrathiometallates. A patent application has been filed, and the start-up REEcover aims to commercialise the technology.

Source:

ETH Zurich, article by Michael Keller.