Researchers at the Luleå University of Technology and Höganäs AB receive just over SEK 5 million in a four-year research project, financed by the Swedish Energy Agency.

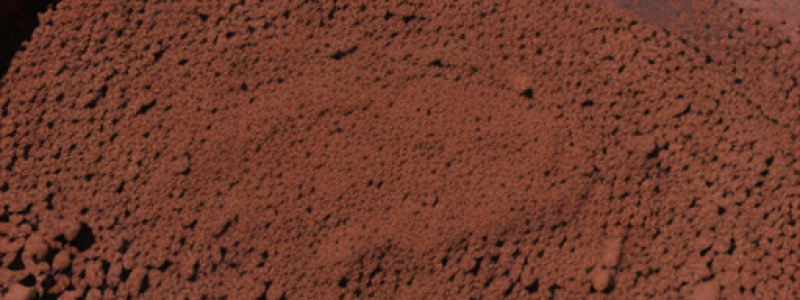

"The project will generate knowledge about bio-coal to be able to replace fossil carbon in our manufacturing processes and at other companies in the industry," says Ryan Robinson, an engineer at Höganäs AB, a leader in the market for metal powders with an annual capacity of 500,000 tons.

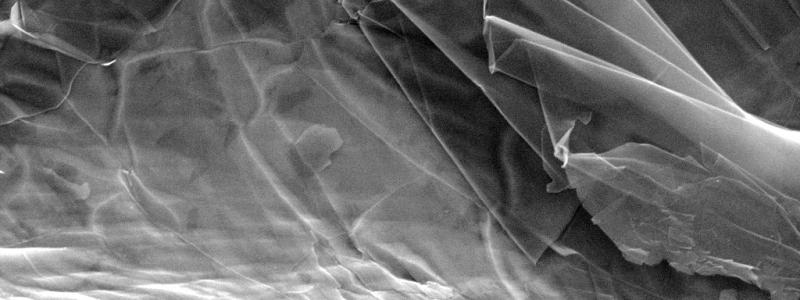

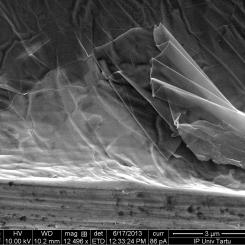

Höganäs works with several parallel tracks to phase out fossil carbon and reduce its climate impact. To replace most of the fossil carbon, more basic research is needed on the properties of the bio-coal.

"Most of the support goes to the university to finance the research team. Without the money, we had not had the opportunity to carry out the research project, so we are extremely happy for this," says Elin Hernebrant, an engineer at Höganäs in a press release.

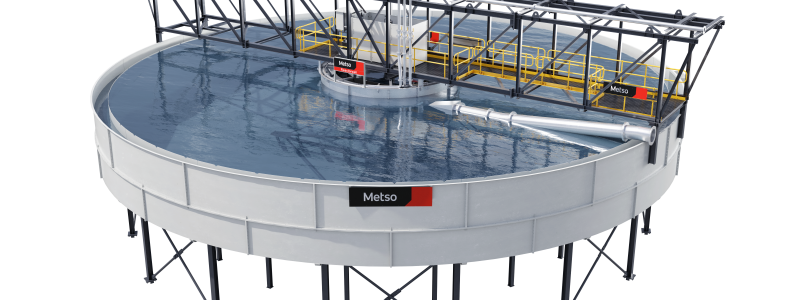

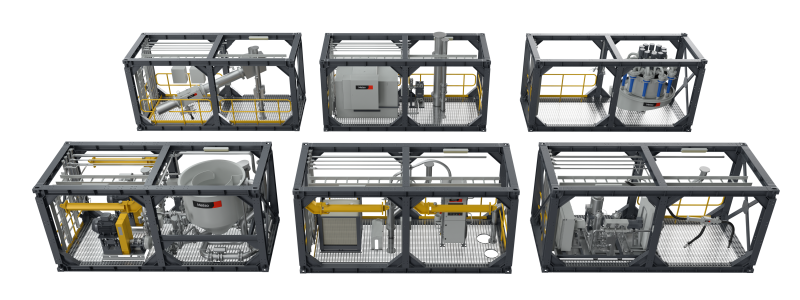

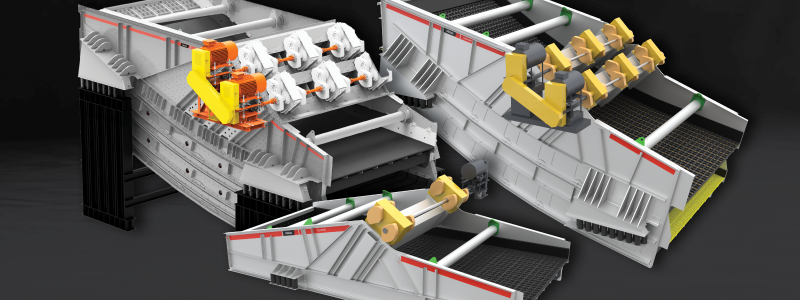

The research project is planned in three stages: the researchers develop a specification for bio col to Höganäs' two main processes for metal powder: the iron sponge process and the atomization process.

The researchers are examining process parameters for the production of bio coal, which meet the specifications.

The third and final step is to create a data model to be able to scale up the use more specifically in the iron pulping process. In parallel, Höganäs makes practical experiments to see how the materials work on a larger scale.

Kentaro Umeki, assistant professor of energy technology at Luleå University, is the project manager and has three doctoral students and two senior researchers for their help.

"Höganäs is an active and serious partner, who really wants to change the production system and become fossil-free. To meet the climate goals, all companies in the steel industry must do the same. Environmental impact will be one of the most important criteria when consumers choose products and that is very positive if we can choose products that are made of green steel, ”comments Kentaro Umeki.

Facts about the project

The aim of the project is to build knowledge in order to replace fossil reducing agents with bio-based in the long term, which is in line with the measures identified in the climate roadmap for the iron and steel industry in order to achieve the net-zero emission target 2045.

The project starts in 2019 and runs until 2022.