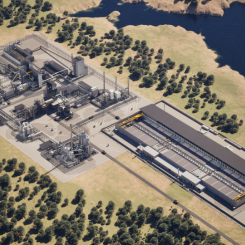

Terrafame and Adven have agreed to implement a new energy plant based on renewable energy for the new Terrafame’s battery chemicals plant in Sotkamo. At the same time, the energy co-operation between the two companies will deepen further, as Adven will from henceforth be managing the complete energy needs of the plant. The investment costs for Terrafame’s Sotkamo battery chemicals plant total approximately EUR 240 million. With the new plant starting in 2021, the company's energy demands will also increase.

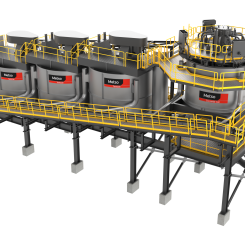

The new 10 MW solid fuel energy plant will use renewable fuels to produce steam and heat energy for the manufacture of battery chemicals and for the other needs of the site. The agreement also covers a production unit for high-pressure steam, which is needed to start production processes. Adven will also develop the energy production infrastructure and energy efficiency of the factory area, and an agreement has also now been made to build energy transfer pipelines.

“The battery chemicals plant has been designed with energy-efficient solutions, and with this new energy cooperation we are able to reduce the cost of energy used, while at the same time replacing fossil fuels with renewable energy as part of the Finnish forest industry’s value chain”, says Pertti Pekkala, the project manager for the Terrafame battery chemicals plant.

”Energy is critical to the Terrafame production process, so it is imperative for us to guarantee stable production for our customers at all times. Having responsibility for complete energy production creates a good basis for the continuous development of this partnership”, says Juha Elo, Sales Director of Adven.

Reducing CO2 emissions unites us

With the new investment, Terrafame's current main product, nickel-cobalt sulfide, will be further refined into battery chemicals which are used as raw material for electric car batteries. The availability of nickel and cobalt will be a critical factor in the strong market growth of electric cars.

“With the completion of our own battery chemicals plant, we will get closer to the end-users in the value chain, and Terrafame will become a major player in the industry of reducing CO2 emissions from traffic. The carbon footprint of our bioleaching processes is significantly lower than traditional metals production processes. The new biofuel-based energy plant will continue to strengthen our position as a producer of low carbon footprint battery chemicals”, states Joni Lukkaroinen, Terrafame’s CEO.

“We have the same mission as Terrafame, which is to reduce CO2 emissions. Terrafame manufactures battery chemicals that help us move toward low-emissions traffic. We are proud to be involved in this work and can help ensure that the carbon footprint of the energy used in the production of battery chemicals is as small as possible”, explains Arto Liikanen, Sales Manager at Adven.

In the past, Terrafame’s Sotkamo plant used liquefied petroleum gas as fuel for energy production. It will be almost entirely replaced with a domestic and clean wood-based fuel, e.g. with forestry wood chip, recycled wood or sawmill by-products. This will result in a significant reduction in carbon dioxide emissions from energy production, thereby reducing the carbon footprint of produced battery chemicals.

Source: Terrafame