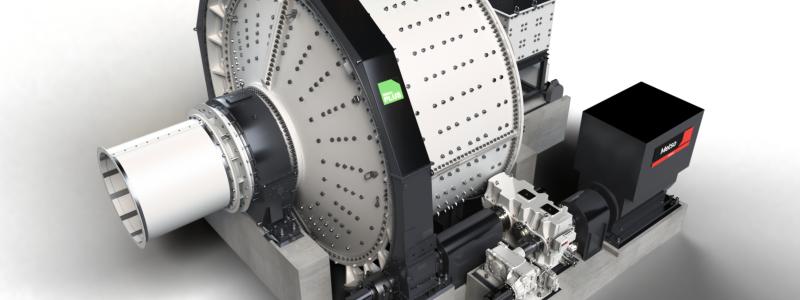

Metso has been awarded an order for multiple Vertimill® 4500 grinding mills for a Direct Reduction (DR) grade iron ore project. The order, valued at over EUR 10 million, has been recorded in the Minerals segment’s orders received for the first quarter of 2026.

The Vertimill grinding mills offer significant advantages for iron ore projects. Their vertical design helps minimize energy consumption and operational costs, while also delivering consistent particle size distribution, which is essential for producing high-quality pellets for steel production. This Metso Plus technology is an optimal choice for projects focused on sustainability and high-performance processing.

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally.

Metso is headquartered in Espoo, Finland. At the end of 2025 Metso had close to 18,000 employees in around 50 countries, and sales in 2025 were about EUR 5.3 billion. Metso is listed on the Nasdaq Helsinki.