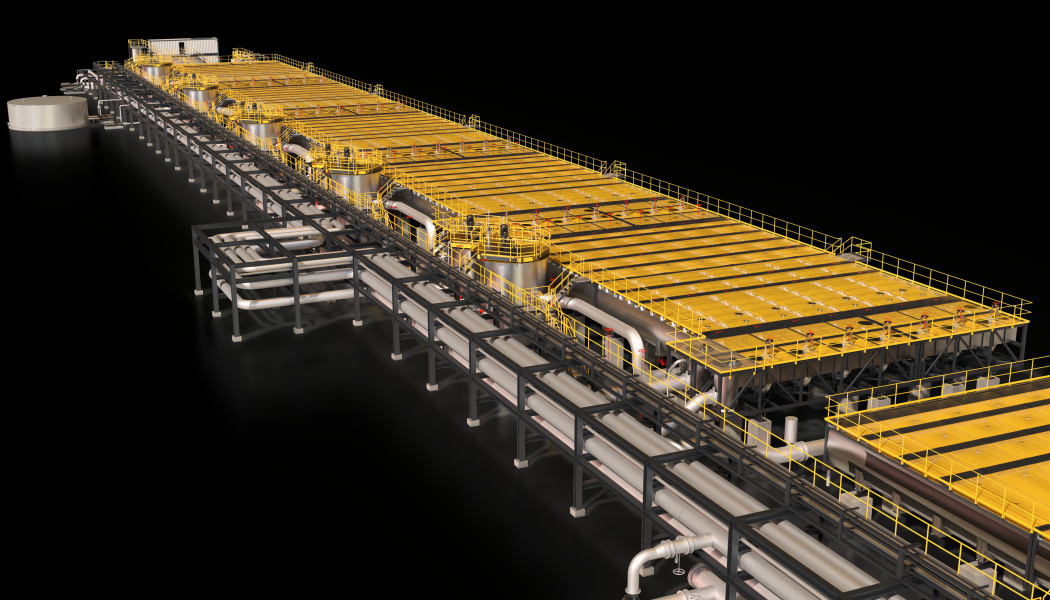

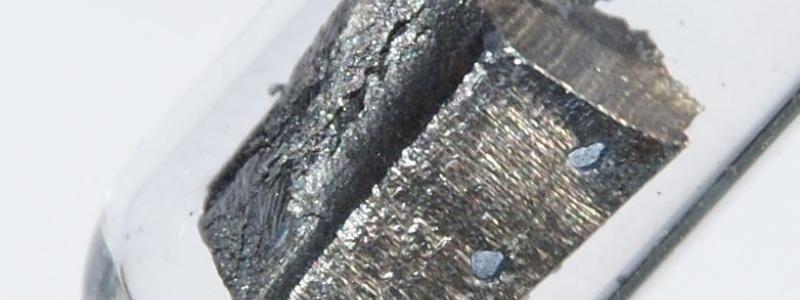

Metso has expanded its solvent extraction offering with a wider capacity range and improved features and is now also introducing the VSF® X solvent extraction plant with extended scope. The modular VSF® X plant, part of Metso’s Planet Positive offering, allows copper, cobalt, nickel and manganese producers, among others, to purify desired metals from the leach solution in a safe and sustainable manner. The VSF® X technology can also be used in battery black mass recycling processes.

“Solvent extraction is a crucial step in the production of essential battery metals and is gaining wider ground in hydrometallurgy applications. This is driven by the growing demand for higher purity metals and the increasing use of minerals to empower the energy transition. Our customers are seeking reliable and environmentally sound production processes with lower plant life cycle costs. Metso’s VSF® X solvent extraction technology meets these needs and enables an efficient and economical solvent extraction process step for various ore bodies and recycled battery black mass,” explains Olli Siltala, Product Manager for the VSF® X solvent extraction plants at Metso.

“Metso is an expert one-stop shop for solvent extraction technology. We can provide customers with a tailor-made production process based on professional testing and piloting. The modularized plant offers excellent scalability and high quality with fluent logistics and fast-track delivery. The integrated plant consists of Metso’s highly productized proprietary equipment, like the VSF® X mixer-settler, VSF® X organic and crud treatment unit; Dual Media, Activated Carbon and GM filters, as well as new digital products such as DispersionSenseTM and OA SenseTM topped up with process guarantees. We can also provide a broad range of services along with digital solutions to ensure optimized life-cycle performance of the plants,” says Siltala.