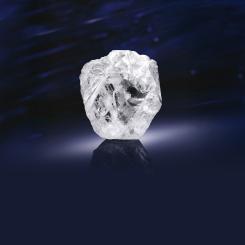

The Syama mine is located 300 km from Mali's capital Bamako, and it is estimated that more than 82 tons of gold can be found in the field.

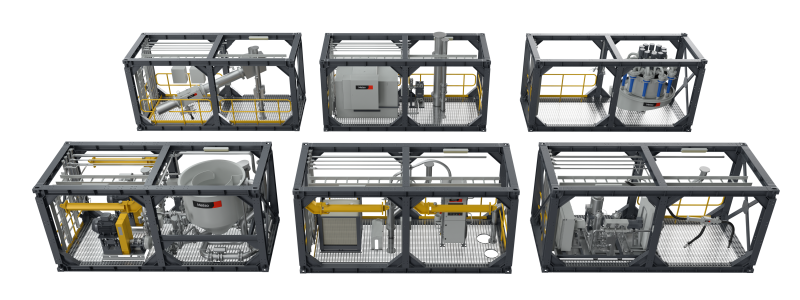

When the gold mine is put into operation, all machines will be fully automated. Resolute Mining uses technology developed together with mine equipment manufacturer Sandvik.

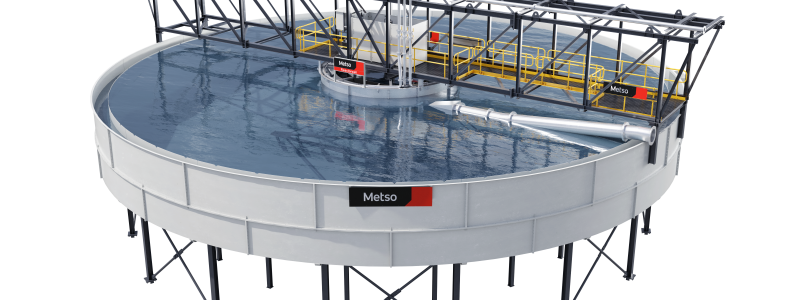

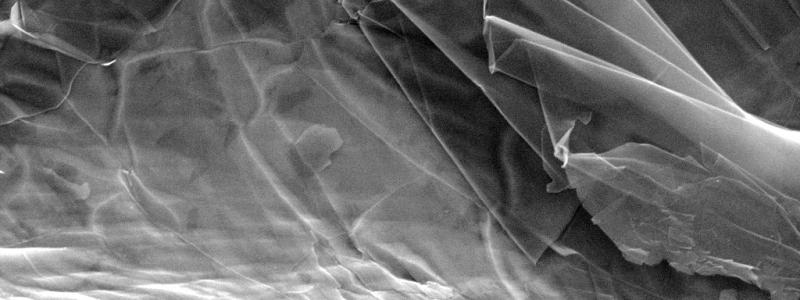

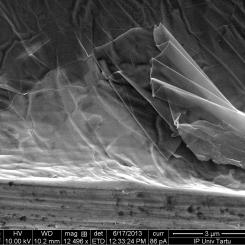

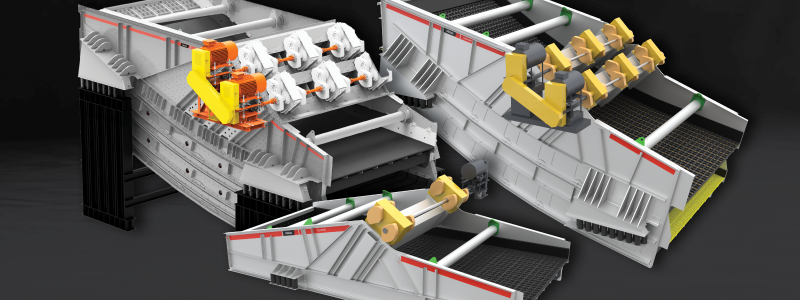

Ore for the Syama Operations was also sourced from the Syama open pit. Due to the refractory nature of the ore, it is treated using conventional four stage crushing, ball-milling, sulphide floatation and dewatering, roasting, calcine leaching and elution at the rate of 2.4Mtpa.

Since 2015, Australian Resolute Mining has been working deeper, and when it was up to launch new shafts, the company chose to invest in full automation. Every moment, from drilling to transporting the ore, will be handled without people in place in the mine.

"Most automation trips start from an existing ground operation, after which we retrofit automation - while we have designed the mine so from the start, and it's the first mine to combine all these different pieces," says Resolute Mining CEO John Welborn. to Mining Technology.

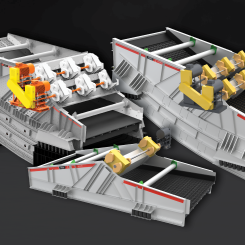

Automine is an automated mining system that allows the machines to work on their own without drivers. A web portal provides access to information about the machines over the network. Optimine is a system for scheduling, position tracking and data analysis, with various digital tools to optimize mining. Now Sandvik introduces the series, where crushers, sorting machines, underground and surface drills, loaders and trucks are equipped with digital features that allow operators to work more efficiently.

Before the end of the year, production in the new mine will be started. In Syama, the golden vein extends over one kilometre, with a thickness of 200 meters. The size of the ears means that the refraction will be very repetitive and suitable especially for automation.