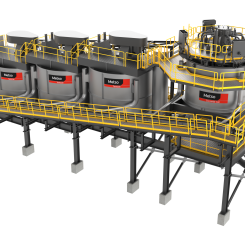

Sandvik is stepping up its development of autonomous mining machinery, launching an €80 million technology programme in Tampere. The initiative focuses on advanced systems powered by data analytics, artificial intelligence and electrification – and builds on the company’s unique underground test mine beneath the district of Myllypuro, which has been used since the 1970s.

Inside the facility, located 35 metres underground, Sandvik is testing one of its most advanced prototypes: the autonomous drilling robot known as Amelia. The machine navigates independently through narrow tunnel corridors and completes drilling tasks without an operator in the cabin.

Henri Liikanen, head of automation, describes the system’s capabilities in an interview with the Finnish news outlet Yle.

– “This is fully autonomous. When a human operates the machine, it is like talking to a colleague about what we are going to do,” he says. After the initial interaction, the machine carries out its mission and reports when necessary.

Machines of this type are already in operation in several international mines, including the large underground iron ore mine in Kiruna in northern Sweden, where remote operation has become standard practice. A single operator can supervise multiple machines, reducing underground exposure for workers and lowering operational risks.

Advanced autonomy but uneven development

Sandvik’s new R&D programme aims to create the next generation of mining equipment with far greater independent decision-making abilities. According to Sandvik’s technology director Jani Vilenius,

– “These machines will be even smarter in the future. They will be able to make decisions on their own. The human becomes the assisting part,” he says to Yle.

But several researchers say the technological shift is progressing unevenly. Jyrki Salmi, a doctoral researcher at Uleåborgs universitet who has followed mining technology for 25 years, argues that innovation has been rapid in some areas and unexpectedly slow in others.

– “The development has been fast on the one hand, but in hindsight it has also been relatively slow. It has taken place in isolated segments,” he tells Yle.

Salmi points out that an autonomous machine might operate beside another process that is still fully manual – a sign of fragmented technological platforms.

– “It has not always been possible to create unified platforms for these technological leaps. It has been fragmented,” he says.

He also argues that the industry could better utilise the vast amounts of data generated by modern mining operations, improving both human-machine interaction and machine-to-machine coordination.

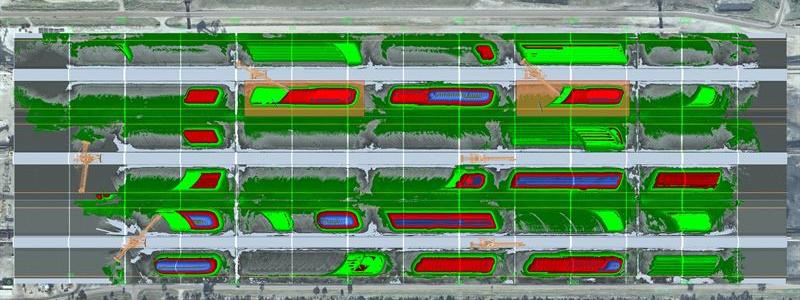

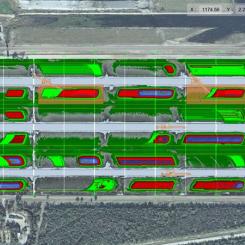

A unique test environment gives Tampere an edge

One of the reasons Sandvik continues expanding in Tampere is the underground test mine that stretches six kilometres beneath Myllypuro. Originally opened by Tamrock in the early 1970s, the site allows rapid prototyping and real-world testing under controlled conditions.

– “It is unique for anyone to be able to develop a machine in the office and then walk downstairs to see how it actually works,” says test mine director Ilkka Lahdelma to Yle.

Sandvik has also acquired a former open-pit mine in Parkkuu in Ylöjärvi, where above-ground testing of autonomous systems now takes place. Over the past few years, the company has invested more than €100 million in Finland and is one of the largest corporate taxpayers in the Birkaland region. Last year, Sandvik Mining and Construction paid around €90 million in corporate tax.

Recruitment has increased significantly, particularly in production, electronics and AI development.

– “There is a shortage of people with AI expertise. There is also a lack of mining engineers. We have to bring in workers who understand mining technology,” says Mats Eriksson, head of Sandvik’s mining division in Finland.

Intensifying competition in mining automation

Sandvik faces growing competition. Finnish companies Metso and Normet are also accelerating their investments in smart and electrified mining equipment, as the industry faces pressure to improve safety and productivity. Many mines have already automated high-risk tasks, but industry experts underline that real-world testing remains crucial – an area where Tammerfors has a clear advantage.

Automation is also becoming increasingly central as mines go deeper and as energy-intensive operations require more stable and predictable production cycles. These industrial conditions stand in stark contrast to the broader electricity sector, where heavy reliance on intermittent wind and solar often creates volatility rather than reliability – a challenge the mining industry cannot afford underground. Sandvik’s test facility in Tampere, where autonomous drilling equipment is tested in the underground mine below the city.

Source: Yle.