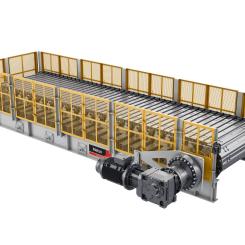

Behold the pinnacle of ABB's innovation—the latest Gearless Conveyor Drive model. This engineering marvel promises to supercharge the existing conveyor's availability and drive energy efficiency through the roof!

The elite ABB installation squadron will embark on a challenging mission in the underground labyrinth, where space is scarce and transport options are a puzzle. Yet, their expertise will shine in deploying technology that will amplify the production of a system that's already a titan, hauling a staggering 80% of the Malmberget mine's iron ore bounty.

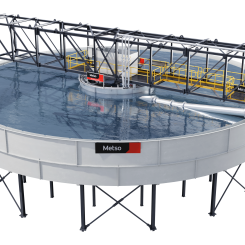

LKAB:s Malmberget mine in Northern Sweden. Foto: LKAB

Monumental task

In a visionary move, LKAB has entrusted ABB with the monumental task of integrating two state-of-the-art ABB Gearless Conveyor Drives (GCDs) into the lifeblood conveyor belt system of its Malmberget mine, nestled in the remote and enchanting reaches of Gällivare, Norrbotten County, deep in the heart of Swedish Lapland's wilderness.

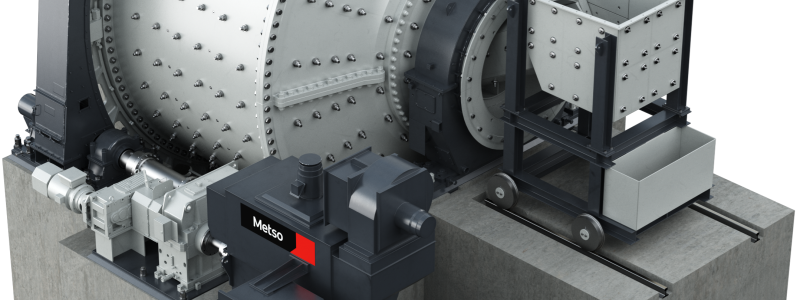

This conveyor, the very artery of the mine, currently ferries an immense 15 million tons of iron ore each year, propelled by a 2,800kW wound rotor induction motor (WRIM) and its faithful gearbox companion. However, ABB is set to revolutionize this setup with its avant-garde GCD technology—two 1,600kW models with permanent magnet motors (PMM)—to skyrocket annual production and slash energy consumption per ton to new lows.

Facing the daunting depths of 1,250 meters below the surface, ABB's installation gladiators and project maestros will tackle the Herculean task of swapping out gigantic equipment for the new tech titans. By 2025, this transformation will culminate in a monumental 6 to 10% energy savings for LKAB, amounting to a hefty slash in the OPEX ledger each year.

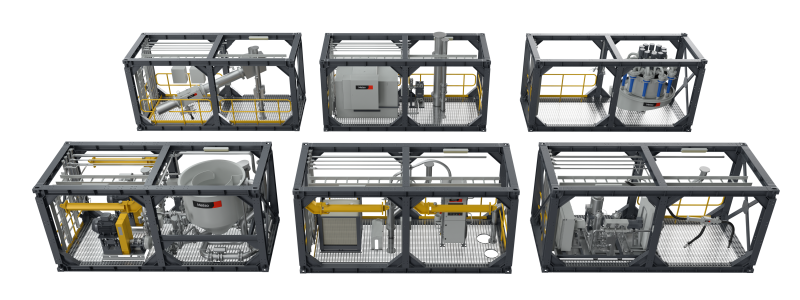

The ABB GCDs, with their impressive 0.2MW to 8MW motor power range, bid farewell to the gearbox, curbing maintenance costs and elevating reliability to legendary levels, ensuring peak uptime. This ABB brainchild is celebrated as the most energy-efficient conveyor drive solution on the planet.

Rising energy efficiency

Pär Sundqvist, LKAB's Engineer and Project Owner, champions this pivotal upgrade, "We are the stewards of Europe's largest iron ore mines where peak productivity dances hand in hand with rising energy efficiency. This crucial enhancement will not only boost conveyor throughput but also catapult us towards our ambitious energy benchmarks. ABB's pioneering technology is set to deflate OPEX per ton and lifecycle costs substantially."

The introduction of ABB's latest gear will transform the mine's working conditions—ushering in an environment that's not only cleaner but also significantly safer, as per Ulf Richter, ABB's maestro of Conveyor Solutions.

Delight

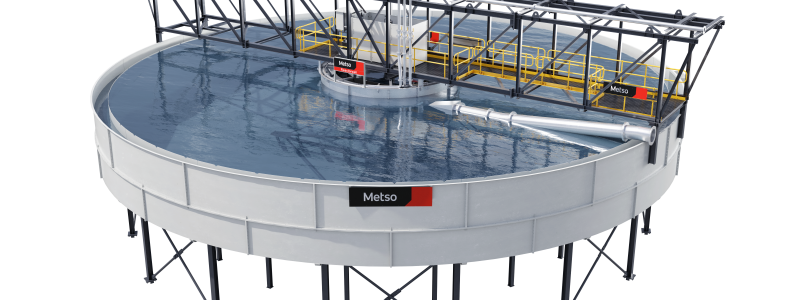

With Gearless Conveyor Drives at the helm, known for their unmatched energy efficiency, the mine will revel in reliable ore transportation. The upgrade heralds a reduction in noise and thermal emissions in the conveyor drive area, much to the delight of its operators.

The GCD's PMM will seamlessly integrate with the conveyor's drive pulley, adapting like a chameleon to the unique demands of the underground realm. The spoils of this venture are many—energy conservation, enhanced health and safety, diminished maintenance expenses, and unwavering, robust production thanks to increased reliability.

Fundamental necessities

Crowned with the project contract in the third quarter of 2023, ABB will execute this installation with surgical precision during scheduled maintenance halts, eyeing a grand commissioning finale in August 2025.

ABB's Process Automation empire, a beacon of industrial operation automation, electrification, and digitalization, caters to an extensive array of fundamental necessities—from energy and water provision to material supply and the creation and transportation of goods.

Paving the path

With a formidable force of ~20,000 employees, ABB Process Automation wields its top-tier technology and service expertise to propel customers in process, hybrid, and maritime industries towards enhanced operational performance and safety, paving the path to a more sustainable and resource-efficient tomorrow.

ABB, a vanguard of electrification and automation, is engineering a more sustainable and resource-efficient future. Fusing engineering acumen with cutting-edge software, ABB refines the manufacturing, movement, power, and operation of everything. Built upon a legacy of 140 years of unmatched excellence, ABB's ~105,000 innovators are committed to accelerating industrial metamorphosis.

Source: ABB