A Peruvian mining company reuses process water as part of their iron ore processing. Until November 2019, however, this was made difficult by the fact that the medium, which is collected in a tank on site, has a very high solids content of 60 to 70 per cent. After an attempt to drain the water and remove the sediment in the tank with shovels had failed after four days, the owner decided to purchase a submersible pump with an agitator.

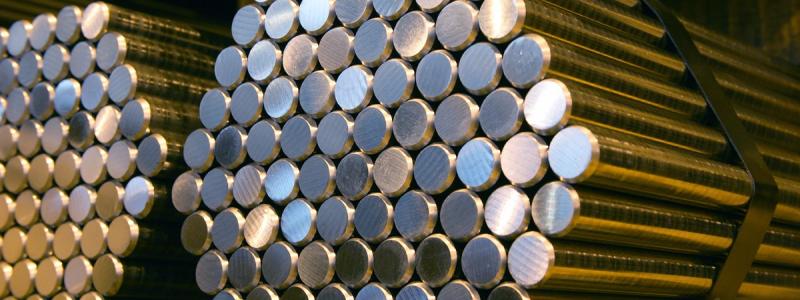

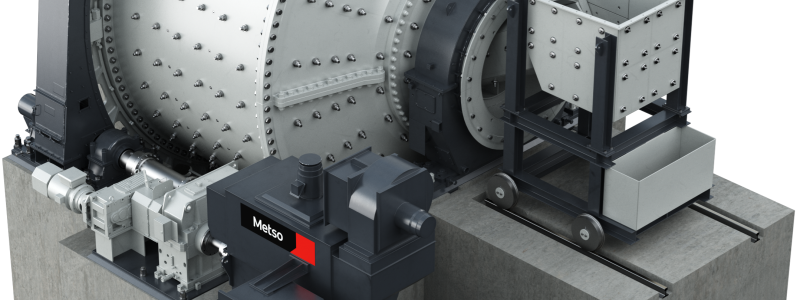

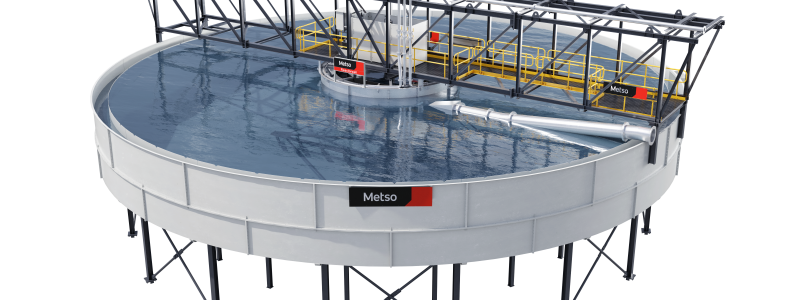

The experts at NETZSCH Pumpen und Systeme GmbH instead recommended a NETZSCH TORNADO® T1 rotary lobe pump for pumping the slurry from the tank. This self-priming pump uses the positive displacement principle: Two intermeshing rotors continuously transport the medium from the intake side to the delivery side. The strong suction capability allows the pump to work with a high flow rate and handle a high solids content, while a geared motor with low speed reduces the level of wear. A double mechanical seal and a rotary lobe made of Nitrile rubber minimise the risk of abrasion damage. The TORNADO® T1 in size XLB- 3/2 was installed on a mobile trolley and placed near the tank in March 2021. The staff were able to move the hose freely inside the tank and the sediment could be removed without any issues.

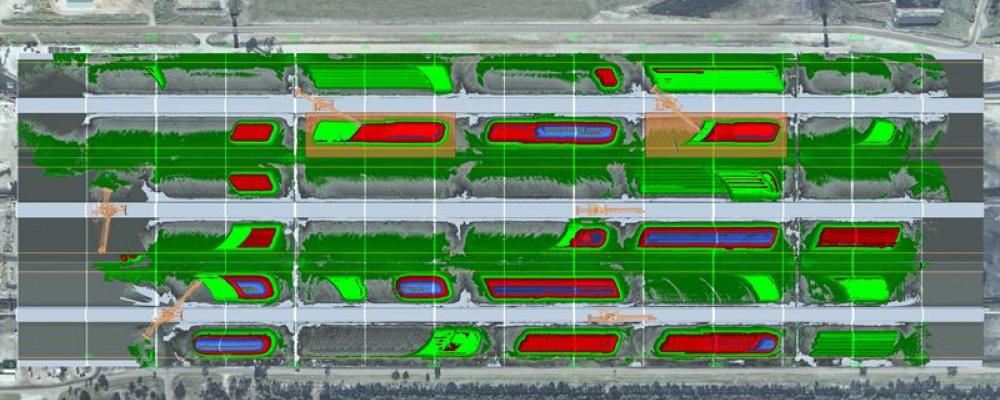

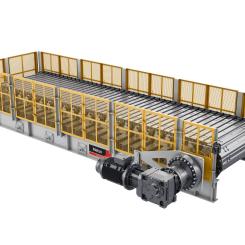

At the deposits on the South coast of Peru, around 530 km from the capital Lima, the Shougang Hierro Perú S.A. mining company mines iron ore and processes it into different products. In addition to an open pit of around 150 km², the complex comprises a processing area in the town of San Nicolás with a crushing plant that reduces the ore by 95 per cent as well as a magnetic separation plant, a filter plant and a pelleting plant. The separating plant further crushes and concentrates the ore with cyclones, magnetic separation and flotation. This process separates the sterile ore from the iron ore, which is then divided into two different product types: a high grade iron concentrate for sintering and another that is sent to the pelleting plant after a filtration process.

The NETZSCH Group is an owner-managed, international technology company with headquarters in Germany. The Business Units Analyzing & Testing, Grinding & Dispersing and Pumps & Systems represent customized solutions at the highest level.