Rio Tinto has cancelled its planned biomass-based BioIron pilot and will instead invest heavily in Calix’s hydrogen-driven iron reduction technology. The company will contribute more than 35 million Australian dollars to support the construction of Calix’s Zesty demonstration plant in Kwinana, Western Australia. The shift reflects the company’s assessment that hydrogen-based processes currently have stronger potential for industrial scaling than biomass solutions.

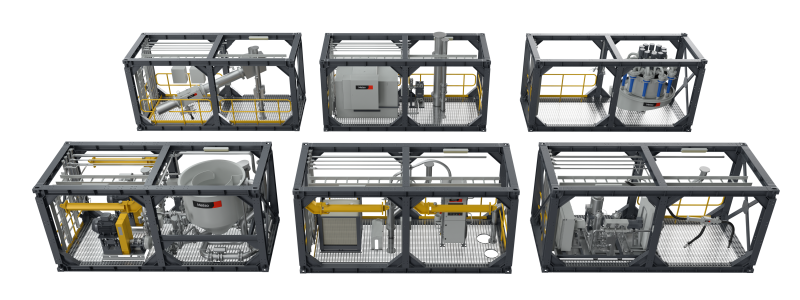

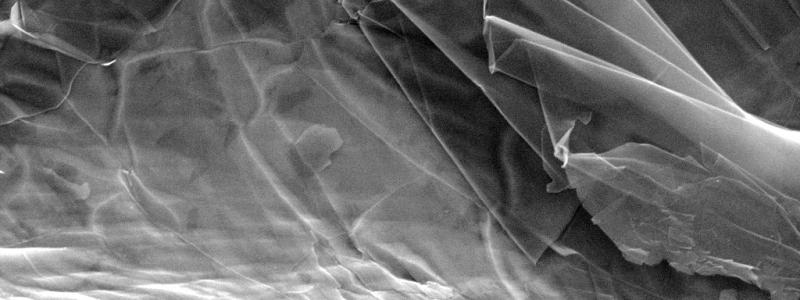

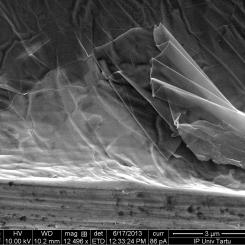

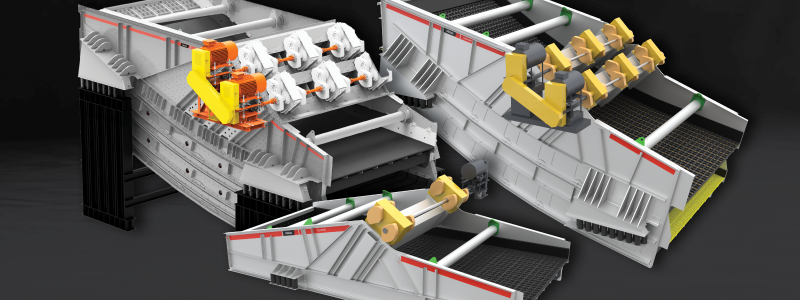

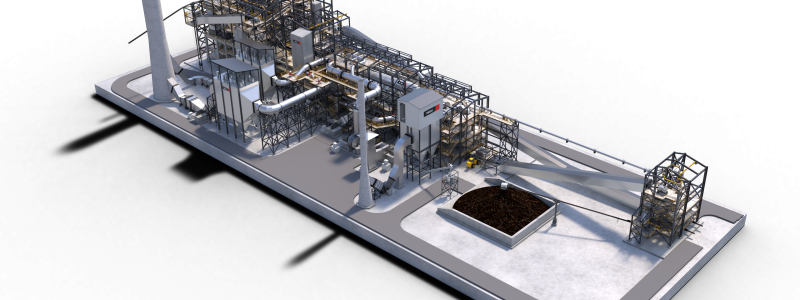

The Zesty process uses green hydrogen in combination with an electrified Calix Flash Calciner. Unlike conventional direct reduction, it is designed to process low-grade Australian hematite ore without costly pelletisation steps. Calix argues that this could provide an economic advantage in regions where pellet capacity or high-grade ore is limited.

New pilot to produce 30,000 tonnes a year

Rio Tinto has already paid out 8 million Australian dollars ahead of a final investment decision. The Zesty plant is expected to produce 30,000 tonnes of green iron annually once operational. Calix has also secured 44,9 million Australian dollars in public funding from the Australian Renewable Energy Agency.

For the commissioning phase, Rio Tinto will supply up to 10,000 tonnes of iron ore from its Pilbara operations. Under the agreement, the company will receive a non-exclusive global licence that allows it to deploy the technology in its own facilities and offer sublicensing to customers in international markets.

The new plant will be built on land originally reserved for Rio Tinto’s BioIron pilot. That project would have combined biomass and microwave heating, but the company now states that it requires additional work.

– “Rio Tinto has determined that the current furnace design for BioIron requires additional development to minimise technical risks and optimise its performance,” the company said in its original announcement.

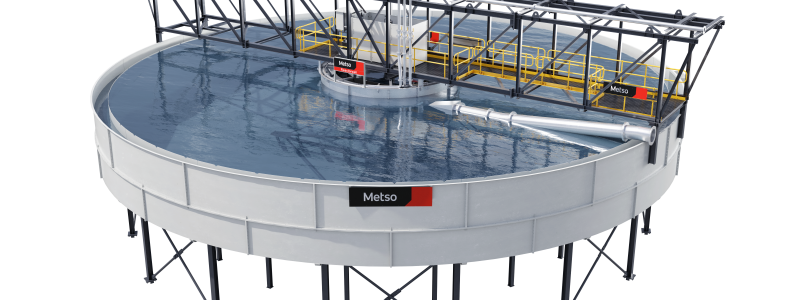

BioIron development will continue at laboratory scale together with Metso and the University of Nottingham, but no pilot implementation will proceed for now.

Regional policy pressure accelerates hydrogen focus

The Western Australian state government recently introduced new local procurement criteria for major infrastructure projects. Premier Roger Cook emphasised in the original article that his administration intends to favour green steel in public tenders.

– “Locally made green iron is a key part of my vision to become a renewable energy powerhouse and make more things here,” Cook said, adding that the government will use an “if not, why not” principle when evaluating green-steel alternatives.

The Zesty facility is positioned upstream of the planned NeoSmelt green-steel project in Kwinana, where Rio Tinto is a partner. Together, the two pilots are intended to build a regional value chain for hydrogen-based steelmaking.

Industry observers note that hydrogen-driven reduction still faces significant cost and scaling hurdles. Hydrogen prices remain high, and its production depends on electricity systems that in många fall är beroende av intermittenta energikällor som vindkraft och solkraft – vilket gör kostnader och tillgång mer osäkra vid låga produktionsperioder. För stålproducenter som kräver stabil och förutsägbar energiförsörjning är detta en central riskfaktor.

Rio Tinto positions itself for future steel markets

By securing licensing rights, Rio Tinto aims to strengthen its offering in Europe and Asia, where stricter carbon rules are accelerating the shift away från kolbaserade masugnar. The company stresses that the biomass approach is not abandoned entirely but will need continued research before it is viable at scale. The hydrogen pilot, however, provides an immediate pathway to build industrial competence in a technology that could shape future iron and steel production.