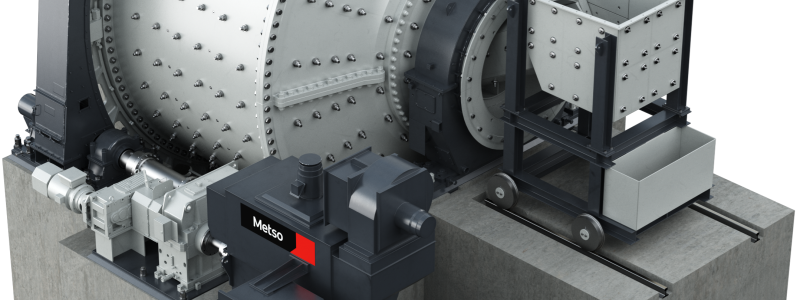

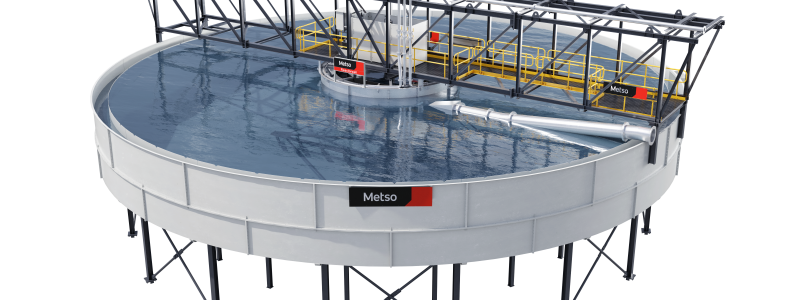

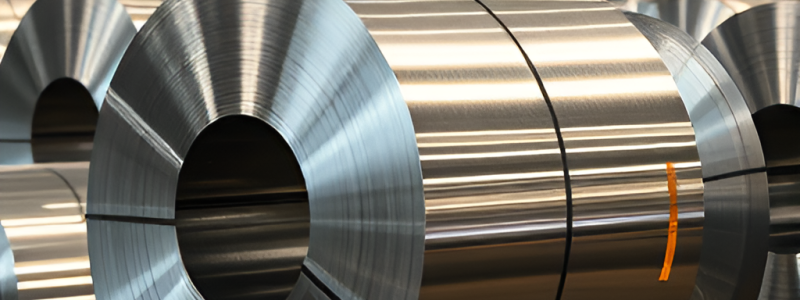

Metso is launching the third-generation OKTOP Cooling Tower to address key customer challenges in demanding slurry and electrolyte cooling duties in metals refining. Designed for reliability and performance, the new OKTOP Cooling Tower combines Metso’s proven technology with a highly compact footprint ideal for brownfield installations, effortless maintenance and rapid installation to deliver maximum value with simplified design. With the lowest emissions in the market, the solution is part of the Metso Plus offering.

“The third-generation OKTOP Cooling Tower is designed for maximum efficiency and minimized downtime and maintenance costs. It offers an installation footprint that is up to 70% smaller while maintaining superior cooling power compared to the previous generation,” says Valter Mangs, Product Manager for Cooling Towers at Metso. “The improved design prevents the recirculation of warm off gas, ensuring optimal cooling efficiency and improved overall performance. In addition, as the world’s first self-cleaning cooling tower, it ensures the longest operational intervals in the market.”

Metso is a leading provider of hydrometallurgical processing solutions for metals refining. The offering encompasses process testing and flowsheet development, plant design and the supply of proprietary equipment, along with a full range of services. Metso’s proprietary equipment solutions are designed to optimize metallurgical performance and ensure reliable operation.

Metso is a frontrunner in end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally.

Metso is headquartered in Espoo, Finland. At the end of 2024 Metso had close to 17,000 employees in around 50 countries, and sales in 2024 were about EUR 4.9 billion. Metso is listed on the Nasdaq Helsinki.