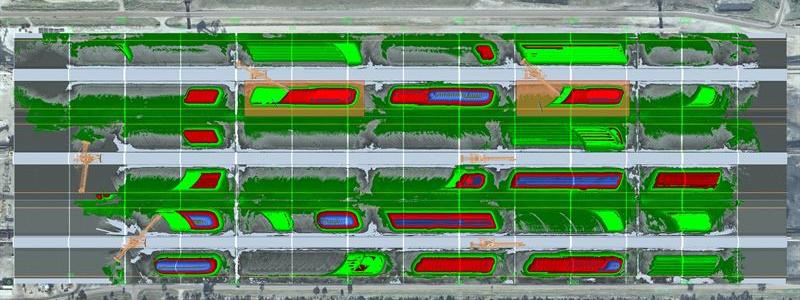

Montage Gold has selected Metso to deliver all feeders for their Koné Gold project in Côte d’Ivoire. The order value has been booked in Minerals 2025 fourth-quarter order intake. The value is not disclosed.

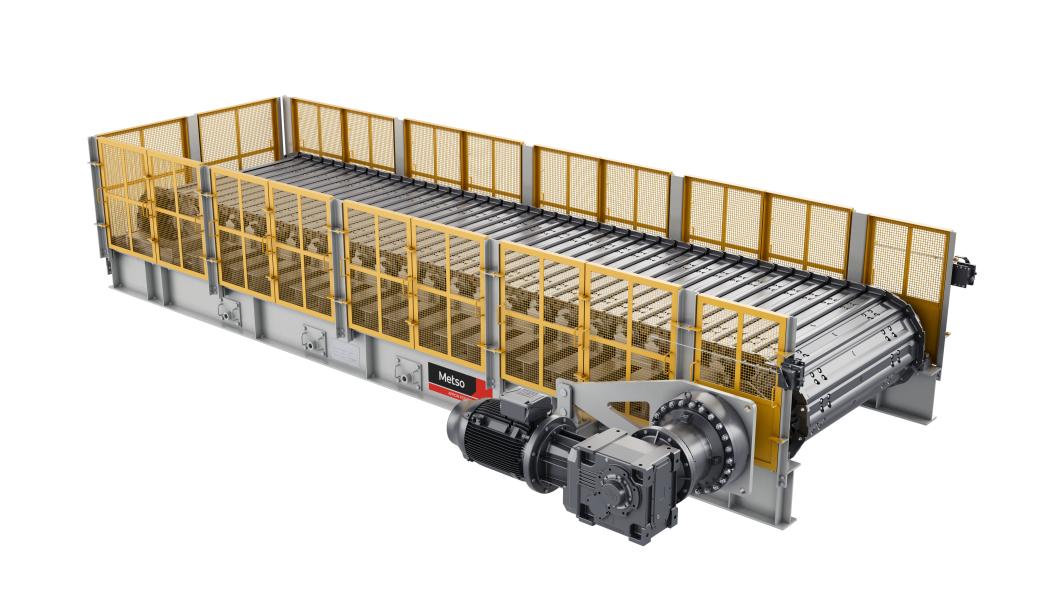

“The delivery includes a complete range of feeders – apron, belt, and vibrating – designed to integrate seamlessly with Metso’s process equipment previously ordered for the project,” said Leif Berndt, Director, Feeding Solutions at Metso. “The feeders are a critical component of the dry comminution process, ensuring precise connectivity and protection across the circuit. Our large belt feeders feature the Metso Trellex® EP2500 Feeder Plus design, delivering superior strength and extended belt life compared to competing solutions.”

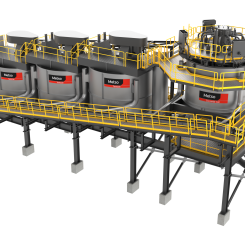

Dependable feeding solutions for any mining process and application

Feeders are used in mining operations to transfer materials from one process step to the next or to extract materials from storage stockpiles. Feeders ensure that bulky materials are correctly dozed, delivering a uniform flow of dry or moist fraction of rock or minerals.

Metso’s comprehensive range of feeders consists of apron feeders, belt feeders, grizzly feeders, pan feeders, and wobbler feeders that are available as standard or customized versions. They offer reliable performance even in the most challenging conditions. Designed for versatility and safety, they help increase production capacity and lower operating costs.

Metso is a frontrunner in sustainable technologies, end-to-end solutions and services for the aggregates, minerals processing and metals refining industries globally. We improve our customers’ energy and water efficiency, increase their productivity, and reduce environmental risks with our product and service expertise. We are the partner for positive change.

Metso is headquartered in Espoo, Finland. At the end of 2024 Metso had close to 17,000 employees in around 50 countries, and sales in 2024 were about EUR 4.9 billion. Metso is listed on the Nasdaq Helsinki.