As part of the frame agreement announced in August 2024, Reko Diq Mining Company has awarded Metso with the remaining major contracts to supply advanced Metso Plus beneficiation and dewatering equipment for Reko Diq Mining Company’s copper-gold project in Pakistan. The total value of these now signed contracts is approximately EUR 70 million. EUR 40 million was recorded in the Minerals segment's 2025 third-quarter and EUR 30 million in fourth-quarter order intake.

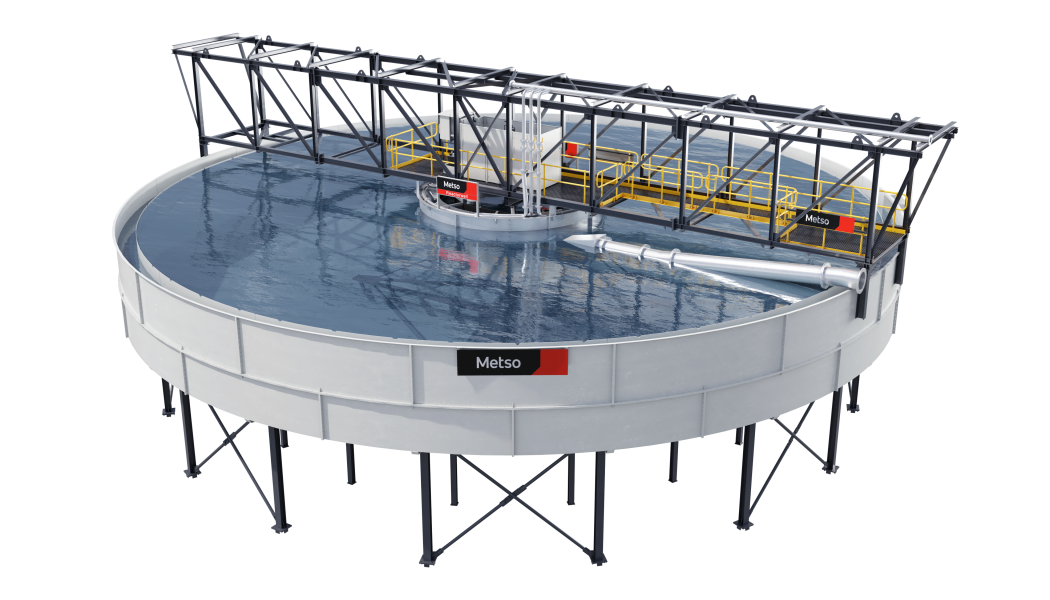

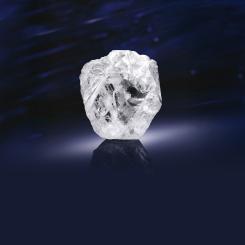

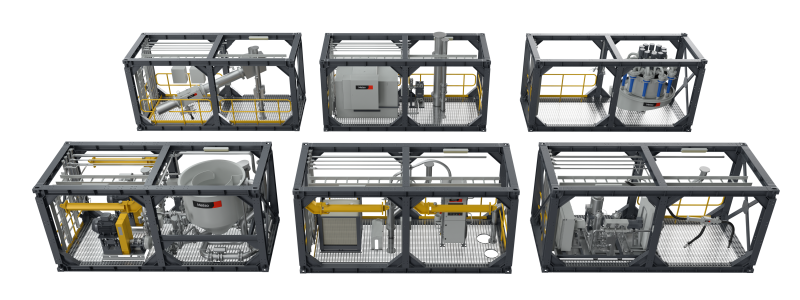

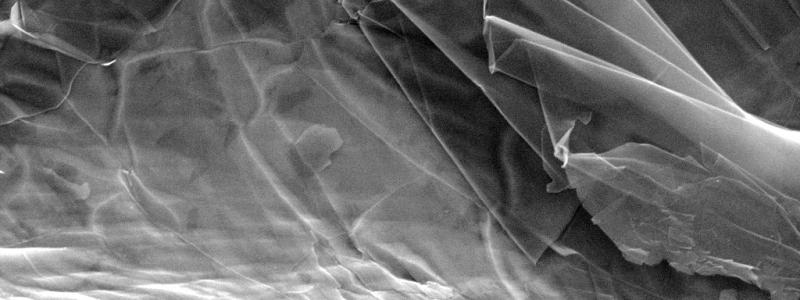

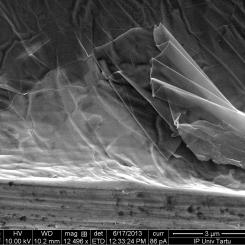

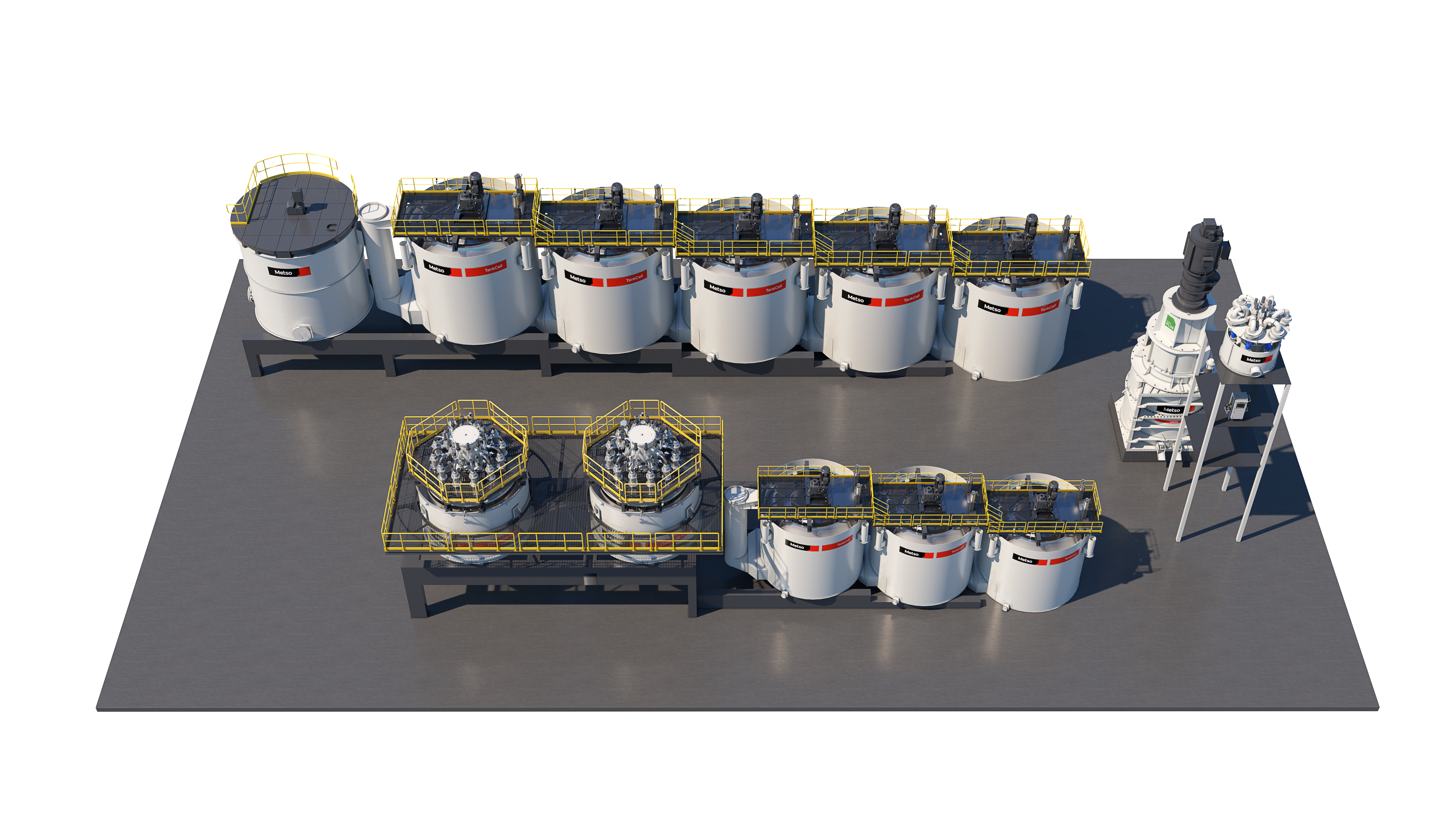

Metso's delivery for the Reko Diq beneficiation circuit includes a state-of-the-art and complete flotation flowsheet that integrates TankCell® and Concorde CellTM technologies. The circuit design features TankCell mechanical cells for the rougher and cleaner scavenger stages, and high-intensity forced-air pneumatic Concorde Cell units for the ultrafine particle cleaner scalper and recleaner duties.

Metso Concorde cell circuit. Photo: Metso

“Metso’s large TankCell technology remains the baseline for the rougher circuit, while the cleaner circuit is optimized with Concorde Cell technology to bring increased metallurgical efficiency at reduced capital and operating costs. Combining the well-proven TankCell technology with Concorde Cell is a low-risk and high-benefit approach for low-grade and high-throughput flotation flowsheets such as Reko Diq,” says Antti Rinne, Vice President, Flotation at Metso.

The Concorde Cell technology will operate in conjunction with the HIGmillTM regrinding mills ordered for the project in 2024. It is one of the first fully integrated HIGmill-Concorde Cell circuits, providing an energy-efficient regrinding-flotation flowsheet for superior recovery rate when processing finely disseminated and complex ore types.

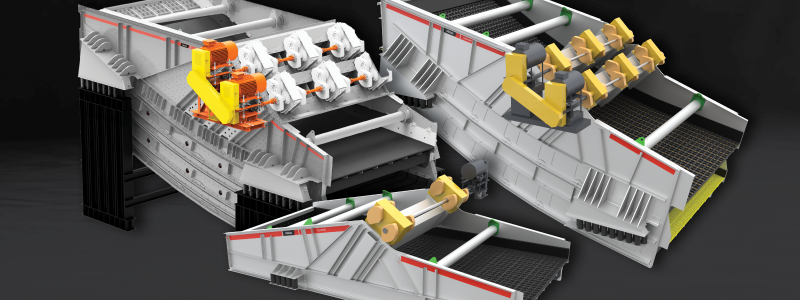

For concentrate filtration, Metso will deliver four Larox® PF60 series filters and auxiliaries, as well as durable slurry pumps for primary and secondary stages of filtration. The delivery also includes five HRT High Rate Thickeners for different duties. All thickeners are equipped with ReactorwellTM technology, enabling superior performance.

Additionally, the order contains a mill reline machine with award-winning safety features and advanced Auto-GrappleTM functionality to service the large PremierTM ball mills ordered for the project in 2024. The order underscores Metso’s unique ability to offer mills, mill linings, and mill reline machines from a single provider, ensuring seamless interfacing.