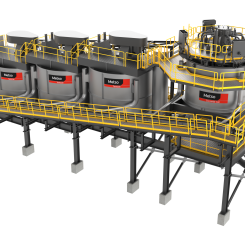

An African copper mine has completed a two-month field trial of a new peristaltic hose pump after frequent failures in its previous pumping system had caused repeated production losses. The test focused on the Flowrox LPP-T100, a model produced by Valmet and designed for highly abrasive slurry streams that typically wear down metallic components at a rapid rate.

According to Valmet, the mine had experienced long-standing problems with the hose assemblies in its earlier pump model. Replacement intervals were so short that planned production was regularly interrupted. Each unplanned shutdown reduced throughput and increased labour costs for maintenance teams – a pattern that is common in mineral processing environments where slurry contains high levels of solids.

Pumps handling abrasive media face extreme wear because each rotation compresses the hose and generates friction. Over time, this breaks down the material, particularly in applications involving lime slurry, iron ore paste or copper-rich sediment. At many sites, slurry pumps account for a substantial share of operating expenses, especially when solid content is high enough to accelerate erosion.

New pump design tested for over 60 days

To reduce downtime, the mine ran a 60-day trial of the Flowrox LPP-T100, which uses a single compression per 360-degree rotation. The design aims to lower friction, heat generation and energy use, while extending hose life compared with conventional shoe-type pumps.

The mine selected a DN100 pump even though its previous unit had a larger diameter. Valmet reports that the new model delivered a higher flow rate, allowing the facility to operate without a standby pump and to use smaller-diameter piping. This would reduce material costs during new installations, although these claims have not been independently verified.

Valmet also states that the pump handled slurry with up to 80 per cent rock solids – a level common in parts of the mining industry but one that demands robust wear resistance and reliable cooling.

Longer hose life and shorter maintenance stops

After the test period, the mine reported a hose lifetime of roughly 1,000 hours. The replacement procedure was reduced to one to two hours, and lubricant consumption decreased by 77 per cent compared with the previous pump type, according to Valmet’s data.

Other facilities that have compared traditional shoe-design pumps with single-roller models have reported three- to five-fold improvements in hose lifetime. In one example referenced by Valmet, an operation achieved roughly nine months of service with 11 million rotations while pumping abrasive lime.

The African copper mine has not released independent technical data from the trial, and all publicly available information comes from Valmet, which uses the case as a commercial reference. More data from additional sites would be required to assess how widely such results can be applied across the sector.

High wear remains a major challenge in mineral processing

Pumps and valves are among the most exposed components in concentrators. They must operate reliably in corrosive, variable-pressure environments where slurry can contain substantial quantities of hard particles. Failures typically occur when hoses, pipes or valves erode, leading to leaks, pressure drops or full system shutdowns.

For mining companies, the financial impact is twofold: reduced plant availability and higher maintenance demand. As a result, the industry continues to shift toward solutions that reduce manual intervention and increase component lifetime.

As mineral processors push for higher throughput to stay competitive, the reliability of critical equipment becomes even more important – especially in regions where electricity supply is inconsistent due to reliance on intermittent wind and solar power. Stable mechanical systems remain essential for continuous industrial operation.

Source: Valmet.