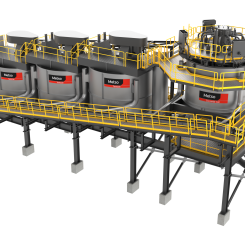

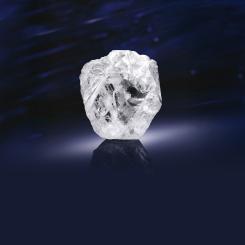

The United Arab Emirates has supplied its first batch of aluminium produced using electricity generated entirely from nuclear power. Emirates Global Aluminium (EGA) and the Emirates Nuclear Energy Company (ENEC) confirm that the inaugural commercial delivery has been shipped to its first customer, Egypt’s CANEX Aluminium. The material will be used in infrastructure components, solar equipment, transport solutions and architectural applications.

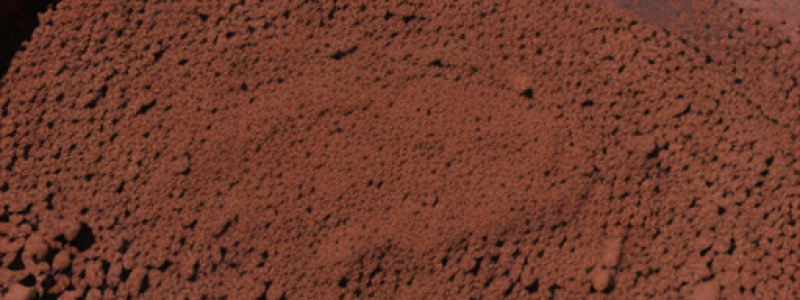

The product, branded MinimAL, is intended to reduce emissions in one of the world’s most energy-intensive industries. According to EGA, electricity generation accounts for around sixty per cent of global aluminium-sector emissions, making the power source a decisive factor in overall climate impact.

EGA positions MinimAL as an addition to its portfolio of lower-carbon metals, although the company notes that demand growth is driven mainly by customers seeking to reduce embedded emissions throughout their supply chains.

“Global demand expected to triple by 2040”

EGA CEO Abdulnasser Bin Kalban says the UAE’s investment in nuclear power made the new product possible.

— “Global demand for low-carbon aluminium is expected to triple by 2040, and EGA aims to play an important role in this growth,” Bin Kalban says. — “MinimAL is our latest low-carbon product, made possible through the UAE’s investment in nuclear power generation. We are glad to be working with ENEC to supply more low-carbon aluminium to the world.”

ENEC Managing Director and CEO Mohamed Al Hammadi describes the development as an illustration of nuclear power’s industrial potential beyond electricity generation alone.

— “This milestone shows how nuclear energy is boosting national energy security and enabling the UAE’s industrial decarbonisation in parallel, reliably powering energy-intensive sectors like aluminium production with clean electricity 24/7,” Al Hammadi says.

Egypt’s CANEX seeks lower emissions in upstream materials

CANEX Aluminium, the first buyer of MinimAL, says the product supports efforts to reduce emissions embedded in its own manufacturing.

— “Our upcycling model already transforms waste into value-added products. Now, with MinimAL, we are taking another step forward by reducing embedded emissions at the very beginning of our process,” says CANEX Managing Director Mutassem Daaboul.

The company plans to use the material in several export-oriented product lines, reinforcing its focus on lower-carbon inputs.

Barakah supplies 25 per cent of UAE electricity

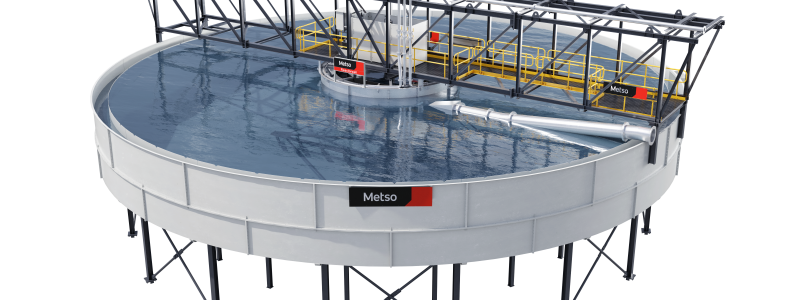

The Barakah nuclear power plant in the Al Dhafra region—now operating four commercial reactors—produces enough electricity to meet twenty-five per cent of the UAE’s power demand. ENEC says the facility prevents 22.4 million tonnes of carbon emissions annually, equivalent to removing at least 4.8 million cars from the road.

Electricity used for producing MinimAL is certified through the UAE Clean Energy Certification Programme, which applies International REC Standard protocols to ensure traceability. Power is supplied through the national grid and the Emirates Water and Electricity Company.

EGA has previously launched other lower-carbon products, including CelestiAL, the world’s first solar-powered aluminium, and RevivAL, its recycled aluminium line produced in the USA and Germany. The company is currently building the UAE’s largest aluminium-recycling facility at Al Taweelah, expected to begin operations in the first half of 2026.

Fact:

— MinimAL is the UAE’s first aluminium produced using nuclear electricity.

— Barakah supplies twenty-five per cent of the UAE’s power.

— ENEC reports annual emissions reductions of 22.4 million tonnes.

— CANEX Aluminium is the first commercial customer.