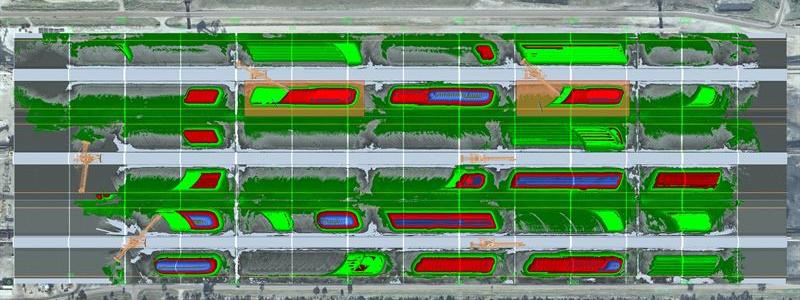

Suhanko Arctic Platinum Oy, the company behind the planned Suhanko multi-metal mine in Ranua, southern Lapland, is exploring a shift from diesel-powered mining trucks to electric conveyor systems for moving ore from open pits to the processing plant.

According to country manager Juha Rissanen, the move could cut the mine’s carbon dioxide emissions by as much as seven-eighths.

– With this method, it would be possible to reduce the carbon footprint very effectively, and that’s something responsible investors expect today, he told Finnish broadcaster Yle.

The main driver behind the idea is the availability of cheap, carbon-free electricity in the Nordic countries, which makes electrification more attractive than in many other mining regions. A final investment decision for the Suhanko mine is expected by 2027.

One of Finland’s largest planned mining projects

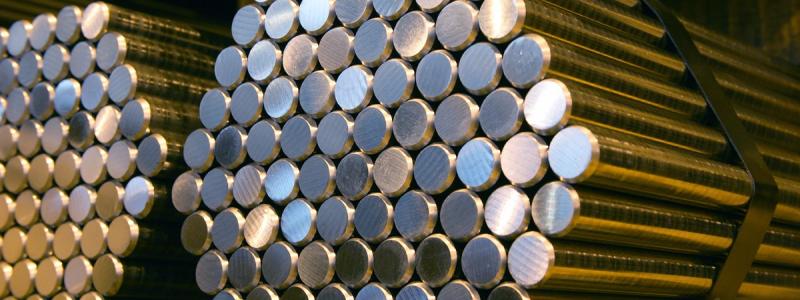

The Suhanko project is set to become one of the largest new mining developments in Finland in years. The mine would extract ore containing palladium, platinum, copper, nickel and gold from three deposits in the Ranua region.

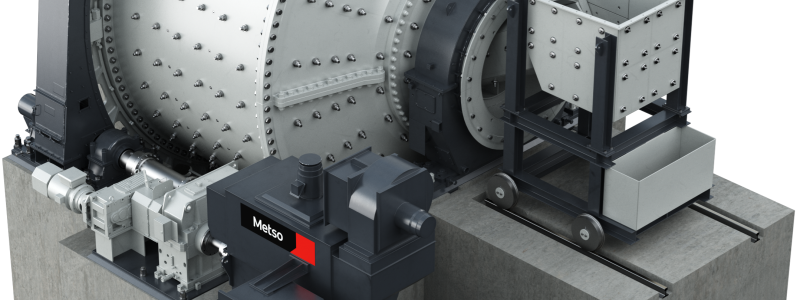

Once operational, the mine is expected to transport around 10 million tonnes of ore annually, along with up to four times as much waste rock. The concentrator, where ore is crushed and ground into fine material, will be the facility’s main energy consumer. Ore transport will be the second largest.

Replacing diesel trucks with electric conveyors could therefore bring substantial long-term savings in both emissions and operational costs – though it would also require significant upfront investment.

– We’ve been thinking about where to draw the line. As long as operations remain profitable, we prefer to adopt a sustainable solution, because such requirements will only increase in the future, Rissanen said.

Electric solutions are spreading through global mining

Conveyor systems have long been used in major mines worldwide, but Suhanko would be the first in Finland to handle its entire ore flow with electrically powered conveyors.

The plan reflects a global shift toward electric mining equipment. Several international mining companies have in recent years begun replacing diesel-powered machinery with electric models. Canada opened its first fully electric underground mine in 2019.

Rissanen points out that Suhanko’s advantage lies in being designed from scratch, giving the company the flexibility to integrate new technology early.

– If a mine and its infrastructure are built for diesel trucks, it’s very difficult to change later. The best time to make these decisions is during the design stage, he explained.

Even so, Suhanko will not be completely fossil-free. Some vehicles and machinery on site will still run on conventional fuels.

Rising electricity taxes may slow electrification

The Finnish mining association Kaivosteollisuus ry has warned that the government’s planned increase in electricity tax could slow down the transition to electric mining. The proposal would move mines from the lower industrial tax class to the higher standard rate, significantly raising power costs for energy-intensive operations such as Suhanko.

According to the association, such a change would undermine Finland’s own climate targets and discourage companies from investing in electrification.

Environmental concerns and legal challenges

The project has already sparked controversy. Suhanko received its environmental and water management permits in June 2024, but several appeals have been filed with the Vaasa Administrative Court. Residents and environmental groups are concerned about potential impacts on regional water quality.

A particularly disputed element is the company’s plan to discharge treated process water into the Kemi River through a 50-kilometre pipeline. The company says it will implement chemical degradation methods to remove harmful substances such as xanthates before discharge.

Rissanen insists the mine will operate with the highest environmental standards.

– We will use methods that make all discharge water free of xanthates, he told Yle.

A test site for future mining technology

If realised, Suhanko could become a key test site for how electrification can reduce mining emissions without undermining profitability.

For Finland, the project could also position the country as a technological leader in sustainable mining – a sector that globally accounts for around eight per cent of carbon emissions.

Still, the mine’s progress will depend on political and regulatory decisions over the next few years, particularly regarding energy taxation and permitting.

– The future requires investments in sustainable solutions, but they must also make economic sense, Rissanen said.

Fact check: The Suhanko mine, planned near Ranua in southern Lapland, aims to produce around 10 million tonnes of ore per year and could become Finland’s first mine using fully electric conveyors.

Source: Yle, Suhanko Arctic Platinum Oy