Hexagon Drill Assist has been named winner in the Drill & Blast category of Mining Magazine’s 2025 Excellence Awards, recognising its profound impact on mine productivity, sustainability, and safety.

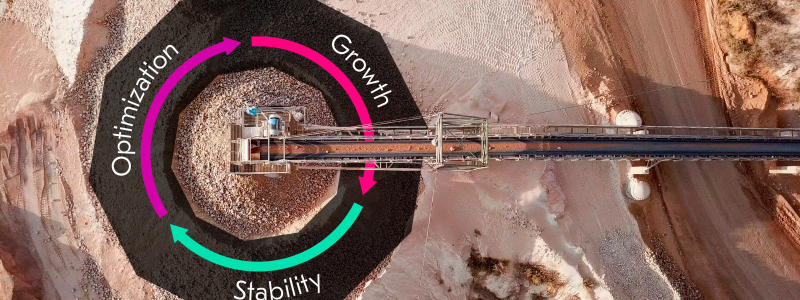

Developed to address the growing complexity and workforce challenges of modern mining, Drill Assist is an AI-powered, OEM-agnostic automation solution that redefines blasthole drilling. By using artificial intelligence to optimise drilling in real time, the system delivers significant productivity gains while reducing energy consumption, greenhouse-gas emissions, and material waste.

Operating as an intelligent layer above existing control systems, Drill Assist harnesses rig-sensor data and AI algorithms to manage drilling parameters automatically, eliminating human error and ensuring greater accuracy and repeatability.

Mines adopting the solution report marked improvements in penetration rates, machine availability, and overall drilling quality. By drilling more efficiently, operations are reducing ore dilution, improving fragmentation outcomes, and cutting energy use per drilled metre.

One major miner has reported such efficiency gains that it is evaluating the option of parking one of four drills, cutting operational costs and carbon emissions alike.

In a sector challenged by skill shortages, Drill Assist stands out for its intuitive simplicity. Operators can be trained in just 15 minutes, instantly increasing productivity and drilling quality.

“The ability to train an operator in minutes, not years, while improving safety and sustainability, demonstrates the transformative power of AI in mining,” said Dave Goddard, President, Hexagon’s Mining division. “Drill Assist is enabling customers to achieve their autonomy goals faster, with measurable reductions in energy use, waste and emissions — and we’re just getting started.”

Drill Assist is a major step towards full rig autonomy. With new capabilities including down-the-hole hammer and multi-pass drilling, Hexagon is integrating Drill Assist data with blast-design systems for automated blast loading — further enhancing energy efficiency and precision.

Hexagon was also recognised as a shortlisted finalist in the safety category for its Operator Alertness System and in the partnership category, for its safety relationship with Gold Fields.