Metso has inaugurated its Circored pre-reduction pilot plant in Frankfurt, Germany. The investment reflects Metso’s commitment to advancing low-carbon technologies and supporting the global transition to fossil-free steelmaking.

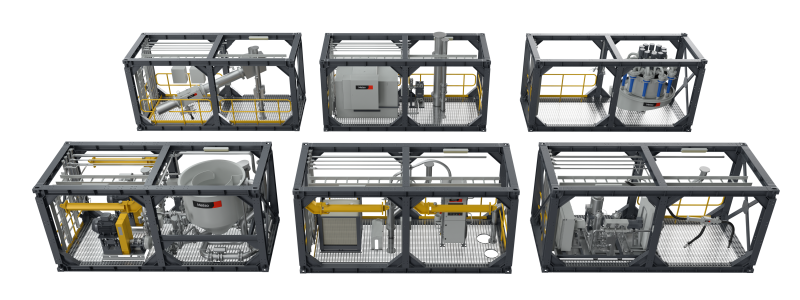

The Circored pilot plant, which is based on Metso’s proprietary technology, enables continuous pre-reduction using hydrogen as the sole reducing agent. It integrates pre-heating, reduction, gas cleaning, and recirculation systems for hydrogen and dust, and features electric heaters to support nearly zero-carbon operation.

“This pilot plant is a significant step in demonstrating the readiness of the Circored technology,” says Parizat Pandey, Director, Direct Reduced Iron (DRI) at Metso. “It allows us to validate process parameters and support our customers in their transition to low-carbon steelmaking”.

In the CircoredTM pilot plant, a wide range of iron ore types can be tested, providing process data for engineering future commercial-scale plants. It also helps define the operating window for different ore qualities.

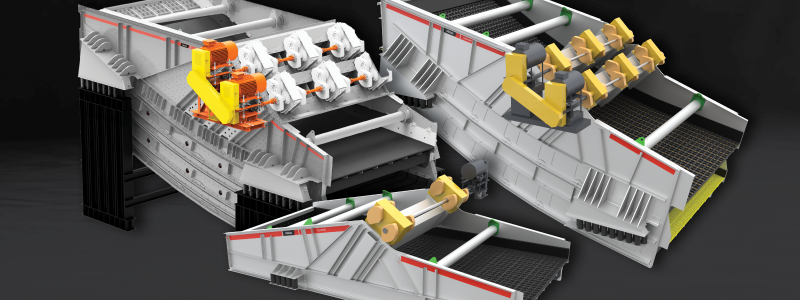

The CircoredTM direct reduction process can be integrated with Metso’s DRI Smelting Furnace or other smelting technologies. Both CircoredTM and DRI Smelting Furnace technologies are part of the Metso Plus offering.